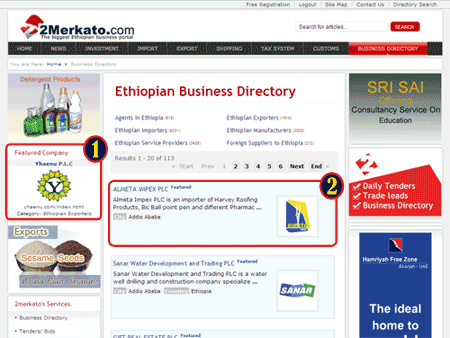

ALLIED CHEMICALS PLC

Opposite Hayaulat Station No. 1, H/Gebreselassie Road, H & M Building, 4th Floor, Room no. 405, Addis Ababa, Ethiopia

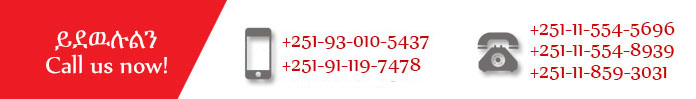

Tel:+251 116 182354 Mobile:+251 911 526352, +251 962 163557, +251 929 907795

Email: Please click here to contact the company via email. http://www.alliedcls.com

Allied Chemicals PLC: Profile and Product Details

Allied Chemicals PLC is a manufacturing company established in 2009 for producing Sodium Silicate which is an essential raw material for Soap & Detergent, Steel Melting & Foundry, Paper Manufacturing & Construction Industry. Currently, we are the only manufacturer of Sodium Silicate in Ethiopia and currently serve 142 big & small manufacturing units engaged in diverse industries. We also intend to export our product to other East African countries namely Sudan, Somalia, Somaliland, Puntland and Djibouti.

1) SODIUM SILICATE (Alkaline & Neutral): Solid Form

Product Specification

- Na2O: 33%

- SiO2: 66%

- Fe: 0.01%

- Solids: 99% +

- Ratio: 2.0-2.3

- Color: Light Blue

- PH: 11.5-12.5

2) SODIUM SILICATE (Alkaline & Neutral): Liquid Form

Product Specification

- Application: Different Industrial Usages

- Appearance: Cloudy

- Specific Gravity: 1.46-1.55 Gm/cm3

- Total soluble SiO2: 29.8

- Total Alkalinity as Sodium Oxide: 14.8

- Rational of total alkalinity as Na2O to total soluble silicate as (sodium oxide/silicon oxide): 2.01-2.25

- Total Soluble Silicate: 44.6

- Total water content: 55.4

- Solubility: Mixable & 100% soluble in water

- PH: 11-12.5

- Feo2: >1%

- AlO2: >2%

- Baum: 40-50 Degree

- Others: >1%

Industry users for Sodium Silicate:

- Soap & Detergent Manufacturers;

- Steel Melting & Foundry Units;

- Others

3) ALUMINUM SILICATE (Al2SiO3)

Physiochemical Properties

|

Physiochemical Properties |

||||

|

Property |

Unit |

Minimum |

Maximum |

Typical |

|

Appearance |

- |

White powder |

White powder |

Average |

|

Bulk Density |

gm/cc |

0.2 |

0.46 |

0.25 |

|

PH value |

% |

7 |

9 |

7.5 |

|

Particle Size |

Micron |

15 |

50 |

35 |

|

SiO2 |

% |

55 |

68 |

58 |

|

Al2O3 |

% |

17 |

30 |

23 |

|

Na2O |

% |

0.2 |

1.5 |

1.2 |

|

Moisture |

% |

0.5 |

6 |

4 |

|

Residue on 180 mesh size |

% |

0 |

1 |

All Pass |

|

Residue on 300 mesh size |

% |

5 |

8 |

6 |

Advantage of using Aluminum Silicate in Paints Production:

- Widely used in the manufacturing of paint, as a less expensive alternative to Titanium dioxide

- Part of white pigment like Titanium-dioxide (10% /more) can be replaced without loss of opacity.

- Give faster surface & through-drying in products which also stand up better to abrasive treatment

- Excellent substrates for high gloss finishes as they ensure good leveling out.

4) PRECIPITATED SILICA

Physiochemical Properties

- SiO2: 85% to 99.5%

- pH: 7

- Bulk Density: 0.07 to 0.20 gms/cc

- Particle Size: 2 to 5 Microns

- BET Surface Area: 140 – 180

- Residue on 350 Mesh: 0.3% Max

- Water Absorption: 160% - 260%

- Moisture content at 105ºC for 1 hr-% max: 5%

Advantages of using Precipated Silica in Rubber Products:

- Improved process ability at equal mixing energy

- Increased tensile strength, tear and flex fatigue

- Improved hysteresis properties superior abrasion (scratch)resistance

5) Linear Alkyl Benzene Sulfonic Acid(LABSA)

- Molecular Formula: C18H30O3S

- CAS No: 27176-87-0

- ELNECS (EC) No: 248-289-4

- RTECS No: DB6600000

- NFPA 704: H-2, F-0, R-0,C-NA

- HS Code: 3402.11

- Synonyms: LAS/LABSA/LABS/DDBSA/Mild Slurry

CHARACTERISTICS

- One of main raw material for household detergents;

- Good decontamination and foaming property;

- Stable in acidic, alkali and some oxide solution;

- The degree of biodegradability is more than 99%;

- Good performance at low cost;

APPLICATION

- As the raw material of detergent, is used to produce alkyl benzene sulfonic acid sodium (LAS) which has the performances of decontamination, emulsification, dispersion, wetting and foaming property.

- Soap& Detergent industry uses for producing various detergents and emulsifiers, such as washing power, detergent of dish-ware, detergent of light or hard dirt;

- Textiles industry uses as cleaner, dyeing assistant;

- Leather making industry uses as degreaser of plating

- Paper –making industry uses as deinking agent.

- Agricultural Herbicides Industry uses as couping agent and as emulsifier, It is used also in emulsion polymerization.

Product Specification

LINEAR ALKYL BENZENE SULFONIC ACID (LABSA)

|

Parameter |

Description |

|

Appearance @250c |

Honey Brown Viscous Liquid |

|

Odor |

Characteristic Odor |

|

Active Matter concentration in % |

96 Min. |

|

Unsulfonate Matter |

≤2.owt% |

|

Free Sulfuric Acid |

≤1.50wt% |

|

Color inKlett (5% Solution, 40mm path, N42) |

40 Max |

|

Boiling Point |

3150c |

|

Solubility |

Soluble |

|

Meting point |

100c |

PRODUCT PACKAGING

- 80Kg/Plastic Barrel

- 16000Kg/Tanker Supply

- Refill in buyer’s barrel also available

Storage:

- Should be stored in dry, cool and ventilated place

- Should be kept away from sunshine and rain

- Stir well before use

6) Sodium lauryl Ether Sulphate(SLES)

- Molecular Formula: CH3(CH2)10CH2(OCH2CH2)nOSO3Na

- CAS No.: 9004-82-4 (SLES 25-3/ 70%)

- HS Code: 3402.1190

- Synonyms:

- Sodium Faty Alcohol Ether Sulfate (AES);

- Sodium Polyoxyethylene Faty Alcohol Sulfate,

- Sodium Laureth Sulfate (SLS)

CHARACTERISTICS

- Excellent decontamination, emulsification, dispersion, Wetting, solubilizing performance and foaming property.

- Good solvency, thickening effect, wide compatibility, Anti hard water and high biodegradable ability.

- Widely used in liquid detergent such as dish-washing Detergent, shampoo, bubble bath,liquid, hand washing etc.

- In washing powder and detergent for heavy dirt, using it to partially replace LABSA, phosphate can be saved or reduced, and general dosage of active matter is reduced.

- In textile, printing and dyeing industry, petroleum and leather industry, it can be used as lubricant, dyeing agent, cleanser, foaming agent and degreasing agent.

Product Specification

|

Parameter |

Specificaton |

|

|

70% |

28% |

|

|

|

White to Yellowish |

Colorless to |

|

Solubility |

Soluble |

Soluble |

|

Odor |

Characteristc odor |

Characteristc odor |

|

Actve Mater in % |

70±2 |

28±1 |

|

Unsulfated Mater in % |

2.0 Max. |

1.5 Max. |

|

Sodium Sulfate in % |

1.5 Max. |

0.5 Max. |

|

1,4-Dioxane in PPM |

50 Max. |

50 Max. |

|

7.0 to 9.5 |

7.0 to 9.5 |

% |

|

Color, Hazen (5% Am. Aq. Sol) |

20 Max. |

20 Max. |

PRODUCT PACKAGING

- 80Kg/Plastc Barrel for SLES 70%

- 200Kg/Plastc Barrel for SLES 70% & SLES 28%

Storage:

- Should be stored in dry, cool place

- Should be kept away from sunshine and rain

- Should remain packed in tghtly secured container

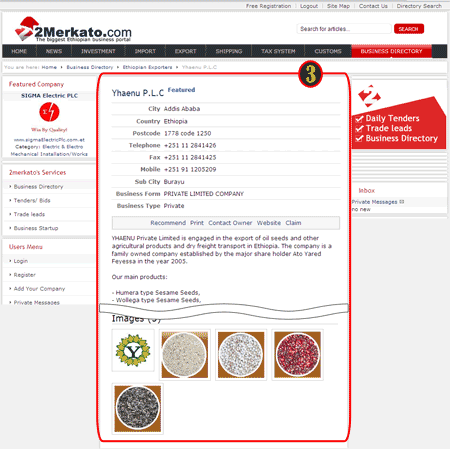

Featured Listing costs

Featured Listing costs