Ayele Marta & Friends Soap & Detergent Manufacturing Partnership Plant establishment in 2011E.C and the enterprise started soap and detergent from Medium scale members in addition to large commercial producers.

The plant was expanded in 2013E.C, and state established to supply soap and detergent by It was further expanded with additional duties so producing affordable products with high quality, micro enterprise producer’s Cooperatives supported by government, supply, Artificial Insemination service etc,

The key functions of the company

- producing bar soap

- producing liquid soap

- Cosmetics products other local market

Mission

- The Mission is producing value added and quality soap &detergents products by collecting raw materials from imports and local supplier’s and then marketing these products to consumers in the local at reasonable price.

Vision

- Ayelumarta and friends soap and detergent manufacturing partenership to continue as leader in expanding market of soap & detergent products in Ethiopia and to have 50% share of the processed products in the local marketing 2025 and also providing raw materials widely like LABSA, SLES, DITTOL CONCENTRATION, SOAP NODDLES.

Overview:

- ayelemarta and friends Partnership Company, pioneering soap and detergent manufacturing company committed to delivering premium quality soap and cosmetic products to consumers in Addis Ababa.

Procurement and Engagement:

- Ayelemarta and friends soap and detergents is deeply committed to sourcing the highest quality of product to ensure the excellence of its detergent products. Currently, the company procures approximately high volume on a regular basis from various sources, including its own shop, These are provided with essential support and resources to enhance the quality and quantity of soap production.

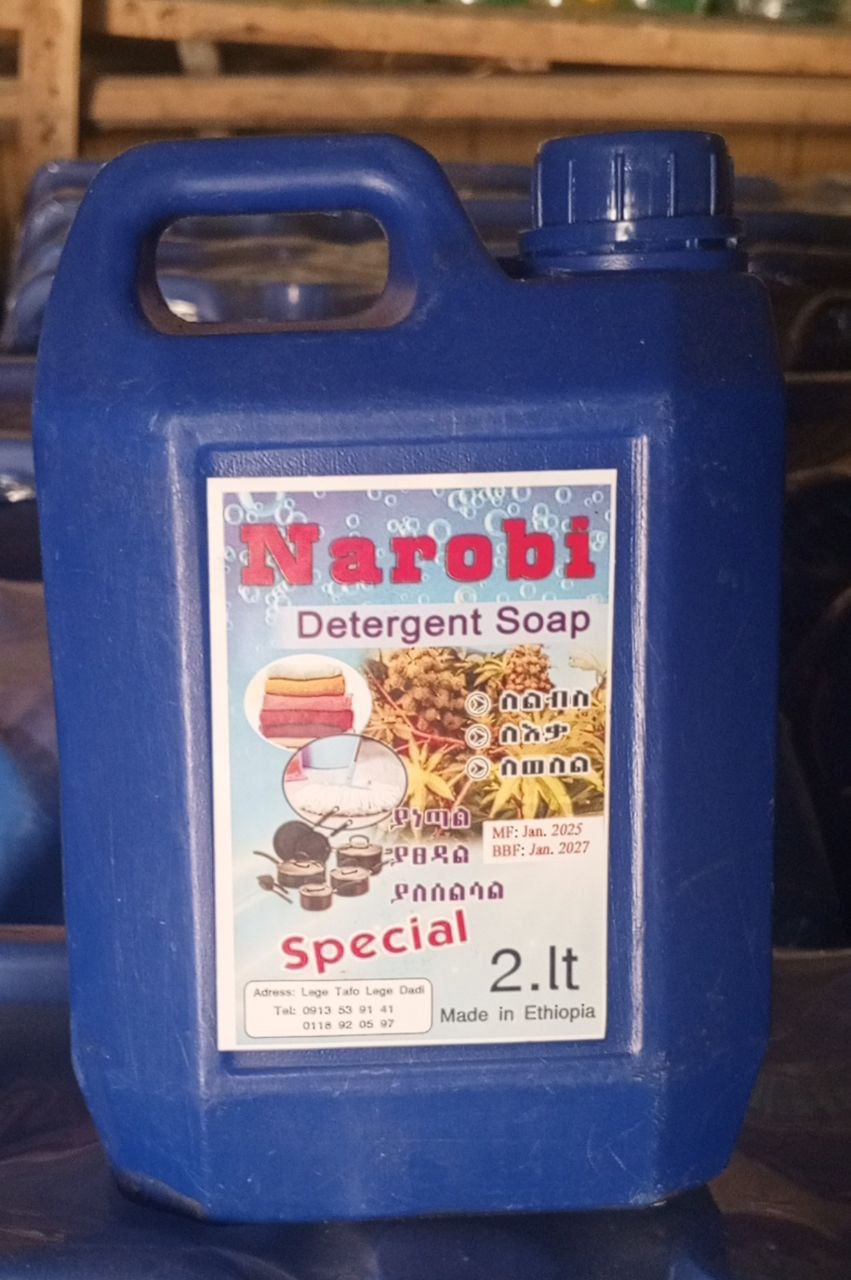

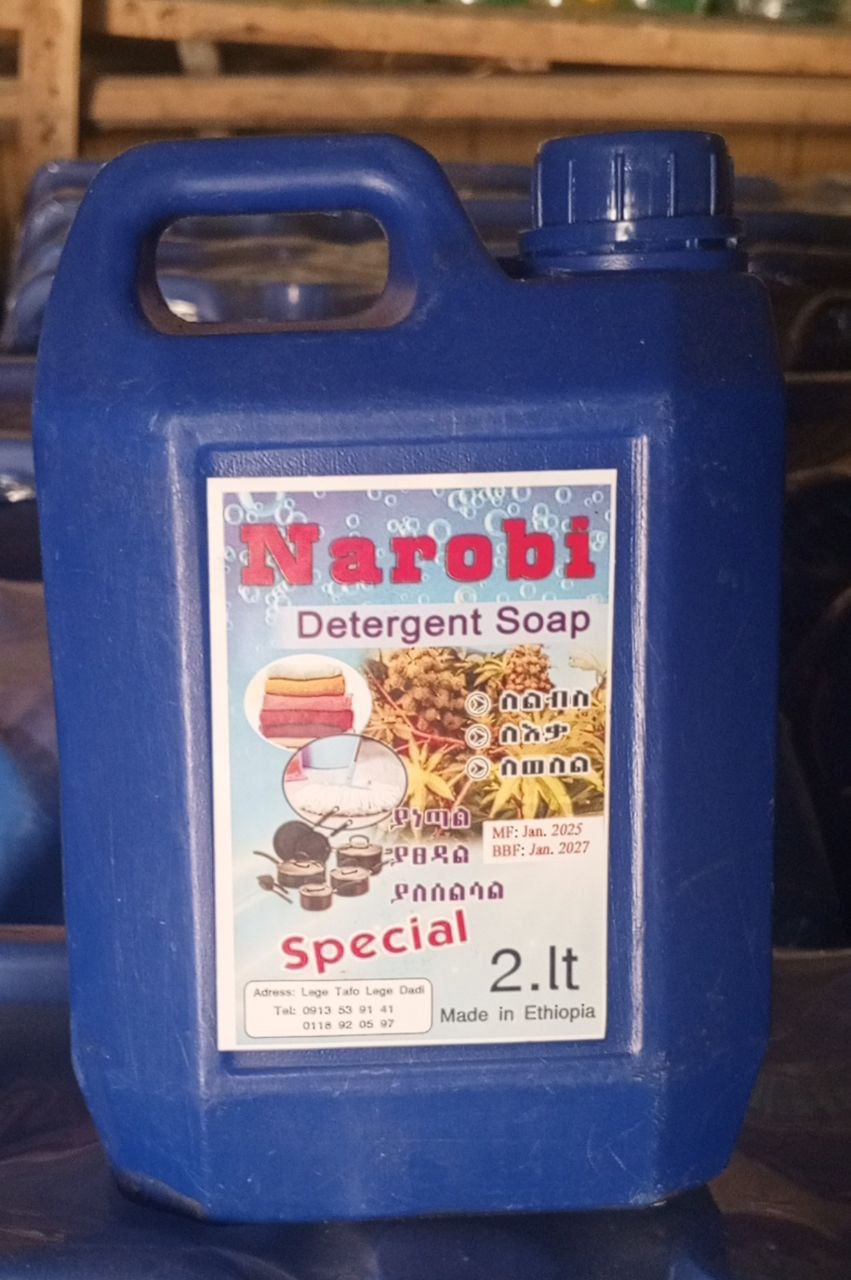

Product of the company

The Main Product of the company

Products: liquid soap and bar soap. Offers a diverse range of products to cater to the preferences of consumers in Addis Ababa.

Our product lineup includes:

- Liquid soap

- Bar soap

- Bleach.

- Shampoo

- Glycerin

- Vaseline

- Dettol

- Conditioner

-

- SANITIZER

- BLEACH

- DITTOL

-

- CONDITIONER

- SHAMPOO

- VASLINE

- GLYCERIN

- paraffin oil

- avocado extract hair food

- DETERGENTS

-

- BAR SOAP

- HAND WASH

- LAUNDARY SOAP

- AJAX

Quality Assurance

At ayelemarta and friends partnership company. we prioritize quality at every stage of the production process. Stringent quality control measures are implemented to ensure that our products meet or exceed regulatory standards and consumer expectations. Our dedicated team of professionals is committed to maintaining the highest levels of safety, purity, and in all our offerings.

PH LEVEL FOR HAND WASHES 7-9

PH LEVEL FOR MACHINE WASHES 6.5-9

Sustainability Initiatives:

We are committed to environmental sustainability and responsible business practices

LOCATION OF THE COMPANY

Company Product shop and factory located in :- sheger city legetfo LEGEDADI

Employees of the company in 2016 E.C

- Male: 10

- Female: 30

- Total: 40

The company has an expansion project currently to enhance our capacity from production to supply,The required machineries and places are prepared currently to reachtothemarket widely

Bar soap

Raw materials preparation ----saponification ----noddles preparation ----mix ----milling ----choting ----molding ----cutting ----packing

Liquid soap

Raw materials preparation ---- leveling ---mixing ---- checking ---- batching ---- packing

Main ingredients for production

- Labsa

- sles

- cdea

- preservative

- Fragnance

Production for bleach

We need to have

- calciumhypoclorate,

- salt

- soda ash

- caustic soda

Dittol

BAR SOAP

Window cleaner

Supplier of raw materials

Our supplier are allied chemicals

- Main raw materials

- labsa

- sles

- cdea

- caustic

- preservatives

REQURMENTS ADDRESED BY IES

RAW MATERialstemporary storage system and checking quality regarding to supplier

we have store for raw materials a place where stored we use fifo system and recognize the ECAE for quality assurance from our providers before taking to production. Then go to production room for producing which we select our product items

Cleaning service procedure

- our producing machineries have cleaning system for each batch for that matter there is high controlling among this area

Handling machinery clean and safety

- First the electric system must be examined and every materials have its guide line to clean if defects happened first the problem must be addressed

EMPLOYEE SAFTEY AND CARING GUIDE LINES

- All employees have safety self-caring facilities and have lessons about how to use and what have to be done

RAW MATERIALS AND MEASURMENT SYSTEMS CONTROLLING MECHANISM

- We also use balance recognized by the expected authority and have recognition paper

COMPLAIN AND RESOLUTION METHODS

- We have clients complain box to gather information about all products

PRODUCT QUALITY CHECKING

- First there is a system to check the base and acidity level then go to correction in every batch

PESTICIDING

- Most of the time our products are disinfectant there is more zero chance to occur but there are products we use sometimes

PACKING AND MOVING SYSTEMS in the store

- The system how to store and to keepmoving safely by our cars and in the shop

- Production room ----> Filing & labeling room ----> Packing ----> Storing ----> Delivering

Procedure to fix machinery

- There is a technician who has knowledge about the machines and there is controlling system within 3 month and when defect happened

TRAINING PROGRAMS

Trainee programs for employee’severy procurement either while working or when hiring them as much as the trainee is needed

- kaizn

- personal safety

- production safety

- production process description

Waste materials removing systems

- Dry wastages are avoided accordingly collected by enterprisesassigned but transfusion applied to recycle for producing other products.

Ware house cleaning

- There is a rotation program between our members for cleaning and there are cleaning materials the warehouse have monthly cleaning program and the production room have every batch cleaning

Production materials checking systems

- By the time there is problem the system used by checking the machinery oil, servicing date and all required

LAYOUT OF CHEMICALS

- Each chemical are placed separately in order to control chemical reaction

- LABSA ----> Calcium ----> hypo chlorate ----> HCl ----> Sles

Prevention from moisture and heat

Direction for air circulation within warehouse

For any polluted air and any suffocation and whereas filtered air circulation system

- all windows must be open during production

- all windows clothed after working activities stop

Safety catalogue

- The company have catalogue to register each remarks and examinations addressed while information is needed

Division of products life cycle

- Raw materials -----proccesed goods ----finished goods

HAZARD AND DANGERIOUS AREAS

- In production areas there may be hazard situation that may hurt or appear danger so that there is caution for safety purpose. There is controlling system to oversee how danger zone is appearing.

Production materials hygiene controls

- In controlling materials hygiene used chemicals for cleaning and water. There is approval catalogue after each cleaning time

RETUREND PRODUCTS MANAGEMENT

- First the returned products go to examination to know what defect occurred and go to fixing if it is over all this go toother product procedure by checking the batch number and the ph level using our recycling room

PRODUCTS UNDER QUALITY

- When products are understated there is mechanism to select and give a correction if it is minor issue and if it is it goes to taking action there is its own room for this process and go back from its batch number

Personal training

- when hiring is done first started by training and giving major topics about all procedures in order to facilitate knowledge

INTERNAL AUDIT

- THERE is an internal audit for every system to check whether there is fraud by having weekly monthly annual report overview

BATCH NUMBERING SYSTEM

- For each product batch number is given

- samples must be taken from each product and batch

- samples must be placed for 24 months for general quality customer analysis

WARE HOUSE LAYOUT

- RAW MATERIALS ROOM---PRODUCTION—FIILLING---PACKING---FINISHED GOODS---APPROVAL ROOM

LABORATORY ROOM

- BEAKE

- ALCHOL METAL

- FLASK.

- TCA TUBE

- BURET

- TUNEL

- DIGITAL BALANCE

- LITMUS PAPER

Contact Us

Address: Current Plant Site (at legetafo legedadi) Sheger city legetfo with Manufacturing

Phone No: 09 13 53 91 41

Email: habtemuabdu40@gmail.com

Telegram: @Narobi soap

Tiktok: @narobisoap