C&E Brothers Steel Factory PLC

| Location | Addis Ababa, Ethiopia |

| Phone | +251 111 26 21 07 |

| Phone 2 | +251 111 26 21 43 |

| Fax | +251 111 26 21 13 |

| Mobile | +251 947 24 24 24 |

C & E Brothers Steel is one of the largest and most reputed steel manufacturers in Ethiopia. The integrated facility sets the standard for the industry with state-of-the-art technologies, skilled manpower, continuous innovation investment, and social responsibility. We have production facilities that manufacture steel bars and wire rods. All our products meet the highest quality standards and comply with both local and international standards. We use excellent raw materials and the latest manufacturing facilities to produce durable and high-quality steel products at excellent market prices. Our cutting-edge technology helps ensure that we can custom build steel products for any industry, commercial or residential applications, and is capable of producing more than 572,000 tons of reinforcement rebar.

C & E Brothers Steel Factory Plc is a private company established on August 14, 2008, G.C. Starting from July 7, 2014, the company will become a joint venture factory of Ethiopia and China’s investors. The total investment cost of the company is above 1 billion Ethiopian Birr.

C & E Brother’s Steel Factory PLC is located in the southern part of the capital city of Ethiopia, Addis Ababa, in a town called Bishoftu, which is 43 km from Addis Ababa.

The C & E Brothers Steel Factory P.L.C. manufactures reinforcement bars in Grade 60, complying with Ethiopian Standard CES 101 and ASTM A617, for domestic and international markets. The company produces;

- Ribbed bar 8mm, 10mm, 12mm, 14mm, 16mm, 20mm, and 24mm

- wire rod 5.5mm to 14mm

- Quartz or Silica Ramming Mass, with different sizes

A new expansion project will be finalized soon, and the following products will be produced:

- Hollow section production line

- The Angle Iron production line

- U-Channel production line

- Flat iron production line

Technology utilization

Recent technology with computerized control systems, Programming Logical Control (PLC), is used for the production of the reinforcement bar. We especially use the following technology:

- Thermomechanical treatment plant for increasing the ribbed bar's strength

- installing a substation of an automatic power factor corrector with a harmonizer. It is used for power stabilization.

- Using an alternate current motor controlled by a programming logical control (PLC) system has a great advantage in proper stability and utilization of power.

- Using an automatic rake type cooling bed with a twin channel bar delivery system,

- Using an automatic finished product packing system

Installation of substation

At present, the company has the following eight transformers with a total capacity of 18,100 kva.

- Three 3500kva units

- Three 2000 kVA units

- One is 1600kva.

After the installation of a substation with a capacity of 50,000 kva, the company uses 31,850 kva and the remaining will be used after the installation of an additional production line in one year.

Our Policy

- The management of the C&E Brothers Steel Factory is enthusiastic about continuously improving its quality management system to the requirements for Ethiopian Conformity Assessment Enterprise:

- Creating a stimulating and rewarding work environment

- Identifying, setting, and achieving the quality objectives is relevant.

- functions by providing adequate resources, training, and developing human resources.

- Providing quality products and services.

- Meeting mutual contractual obligations.

- Ensuring customer satisfaction.

- Enhancing productivity and efficiency.

- Achieving business leadership by devotion

- Review quality policies periodically.

- To maintain the high quality of our products. The physical and chemical properties are continuously monitored and tested according to specifications using universal testing machines, optical emission spectrometers, and other related testing and quality control equipment. From raw materials to finished goods, ECAE meticulously checks its products for high quality, and it has a world-class in-house material testing laboratory.

With this modern technology, we assure you that our plain and deformed bars are manufactured to conform to national and international standards for low, medium, and high yield strength applications.

Production Capacity

Our company produces different sizes of reinforcement bar, coiled wire, and wire rods used mainly for the construction industry with different grades. The factory has a capacity of 572,000 tons per year and produces three types of products: reinforcement bar, wire rod, and wire.

Vision

To be East Africa’s most reliable and innovative manufacturer of the steel industry.

Mission

To supply high-quality steel products, providing related services and solutions to a continent-wide client base while utilizing innovative technologies within an environment of motivated employees focused on continuous improvement, the highest business standards, work ethics, and corporate citizenship, leading to added value to our customers and a sustained return on investment for our shareholders.

Values

Customer Satisfaction

We strive to excel in our business and satisfy our customers.

Quality Service

We are committed to offering quality service to our customers and aspire to be branded with quality in the minds of our customers.

Innovation

We encourage new ideas that can improve customers’ experiences and the factory’s performance.

Teamwork

We take pride in our ability to pool resources and effort aimed at achieving our common goal, which is to realize our vision.

Employees

Our employees are our most valuable organizational asset.

Our strength

- Consistent quality

- Competitive Price

- On time delivery

- Prompt Service

- Technical Expertise

- Professional Approach

Our Products

- 8mm to 24mm Reinforcement Bar

- 6mm to 14mm wire rod

- Quartz or Silica Ramming Mass in Different Sizes

Product Quality

C & E Brother’s Steel Factory PLC ensures with its quality assurance processes and the following material properties that conform to the standards indicated below: Grades II, 60, and 75.

Mechanical Properties

Minimum Yield Strength: 500 Mpa

Tensile Strength: 550 Mpa

Economic contribution

The major economic contributions of the project are the following

- Import substitution

- Support the sector's government policy and strategy.

- Employment Opportunities

- fill the demand-supply gap in the sector.

Some of our current clients

- Addis Ababa Housing Agency, 20/80 and 40/60

- Afrotsion Construction

- TNT Construction

- Quantang Construction

- China State Construction Eng. Co. Eth. Ltd.

- Yotek Construction

- Rama Construction

- Ellilta Construction

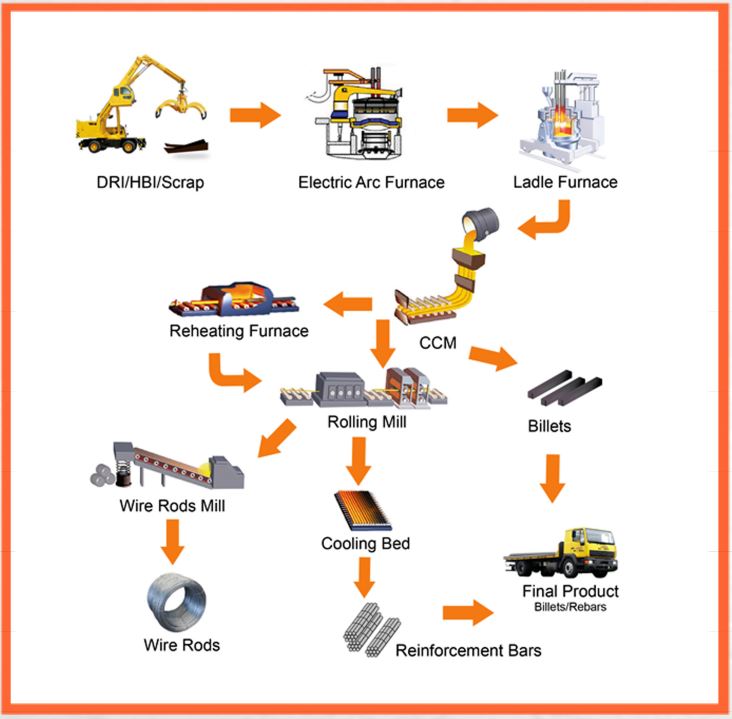

Our Production Process

CONTACT US

Location: Tracon Tower, 7th Floor, Office No. 701, in front of Tikur Ambesa School, Addis Ababa, Ethiopia

Phone 1: +251 111 26 21 07

Phone 2: +251 111 26 21 43

Mobile 1: +251 947 24 24 24

Mobile 2: +251 947 38 38 38

Fax: +251 111 26 21 13

E-mail: candesteel@gmail.com

Website: https://candebrothersteel.net/