Tana Drilling and Industries PLC (TDI)

| Location | Addis Ababa, Ethiopia |

| Phone | +251 114 71 76 42 |

| Phone 2 | +251 114 71 79 24 |

| Phone 3 | +251 114 71 77 52 |

| Sub City | Akaki Kality |

| Woreda | 7 |

Tana Drilling and Industries PLC (TDI) is a family-owned company and was established in 2004 in Ethiopia. Its primary business function was Deep Well drilling for rural, municipal, and other communal water development projects. During this time the company has seen reputation and steady growth and has drilled over 500 deep wells around Ethiopia.

TDI's vision is focused on creating cost-effective high-quality products which will ensure a long-lasting infrastructure. To achieve this, we have installed state-of-the-art manufacturing equipment from Germany and Italy, and we only use the highest quality pure grade resins for all our products. This combined with our highly skilled workforce ensures that only the highest quality pipes are produced.

In meeting Ethiopia’s growing demand for HDPE and uPVC pipes, TDI constructed two states-of-the-art manufacturing plants equipped with the latest manufacturing technologies producing HDPE and uPVC Pipes located in the Akaki/Kality sub-city industrial area in 2015, with a combined production capacity of over 38,000 MT making it the largest manufacturing facility of its kind in Ethiopia, actually larger than all the existing large pipe plants combined.

TDI develops, produces, and markets a comprehensive range of piping systems in a variety of materials used worldwide to transport water and wastes at the highest quality, service, and price range. TDI’s HDPE and uPVC pipes are suitable for water distribution networks, drainage and sewerage systems, chemical, gas, and water conveyance, sewer and water purification systems, Agriculture and Irrigation, and electrical and telecommunications distribution systems. TDI operates in three core segments: Building technology, Utility application, and Agriculture.

TDI is a certified ISO 9001:2015 company and manufactures all its products to international standards. It is equipped with a state-of-the-art testing laboratory that conducts a rigorous testing administration focusing on every aspect of the production process from resin entering the factory to the end product being delivered to the customer. As a result of the meticulous quality control approach and testing, the product quality of Tana Drilling and Industries PLC is confirmed by its local and international quality certificates. TDI gives top priority to using the highest standard of technology to manufacture user-friendly products with the highest quality and service.

Vision

To be the regional leader of water supply systems in the African continent by providing a full customer solution from design to commissioning in conjunction with the supply of high-quality cost-effective pipes and deep well drilling services with a goal of being a major contributor in the drive for clean water access for all.

Mission

Through its state-of-the-art manufacturing facilities and extensive experience in the drilling and installation of water supply systems, TDI will seek out and build partnerships with local and regional customers to produce innovative and cost-effective products and services.

Why Choose TDI HDPE and UPVC Pipes?

PRODUCT CONFIDENCE

TDI uses only the highest grades of resins and additives in the manufacture of all its pipes. No reprocessed plastic is used to reduce manufacturing costs. TDI will never compensate quality over cost by using substandard resins and reprocessed plastic waste. This means you can be 100% confident that when you purchase a TDI pipe it will perform as per the standard it has been manufactured to. An HDPE pipe will have a minimum lifespan of 100 years and uPVC will last a minimum of 100 years.

TDI uses only the highest grades of resins and additives in the manufacture of all its pipes. No reprocessed plastic is used to reduce manufacturing costs. TDI will never compensate quality over cost by using substandard resins and reprocessed plastic waste. This means you can be 100% confident that when you purchase a TDI pipe it will perform as per the standard it has been manufactured to. An HDPE pipe will have a minimum lifespan of 100 years and uPVC will last a minimum of 100 years.

MANUFACTURING EXCELLENCE

TDI uses state-of-the-art European manufacturing equipment for the production of all its products. Critical aspects of the production process are constantly monitored and controlled by various systems incorporated into the equipment. This in conjunction with our highly trained workforce ensure consistent quality for each and every pipe produced.

TDI uses state-of-the-art European manufacturing equipment for the production of all its products. Critical aspects of the production process are constantly monitored and controlled by various systems incorporated into the equipment. This in conjunction with our highly trained workforce ensure consistent quality for each and every pipe produced.

QUALITY CONTROL

TDI has been certified by the Ethiopian Conformity Assessment Enterprise to manufacture HDPE and uPVC pipes. All aspects of TDI’s products are stringently tested following the ISO requirements from the resin entering the factory to delivery to the customer. TDI is equipped to test almost all pipe quality related parameters which ensures only the highest quality products reaches the customer.

PROFESSIONAL EMPLOYEES

Our employees are at the heart of our business – everything we do, and our success, is dependent on them. Our employees are engaged, and have the skills and knowledge the industry demands to perform their roles. They have the ambition to grow, develop and feel fulfilled which is essential for satisfying our customers, and for TDI to prosper as a company.

Description of Product Lines

The products of TDI are categorized in two major product lines namely, U-PVC pipes and HDPE pipes and fittings. The following chart represents/depicts the product lines.

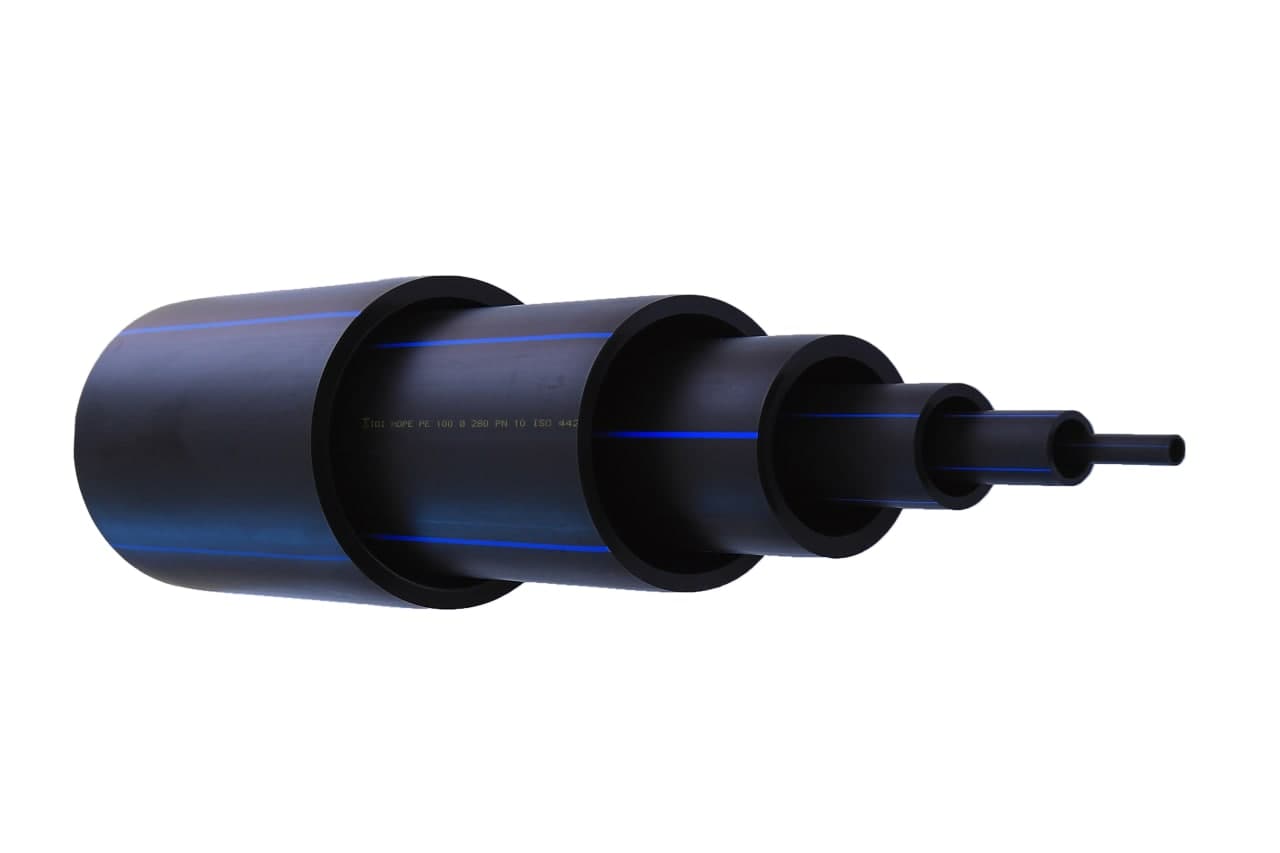

DENSITY POLYETHYLENE (HDPE)

TDI’s HDPE pipes have properties of high strength and flexibility, damage/chemical resistance, superior flow characteristics and versatility. All TDI pipes are manufactured to ISO 4427 and can be confidently used with the applications listed below,

- Industrial: Chemical, Gas and water conveyance, and sewer & water purification systems.

- Civil Engineering: Water mains and other water distribution networks.

- Building: Industrial and Residential water distribution networks.

- Mining: Water/Slurry conveyance.

|

Standards: |

ISO 4427 |

|

Material |

PE100 |

|

Joints |

Butt-fusion, Electro-fusion, and Compression Fittings |

|

Temp. Range |

0˚C - 60˚C |

|

Tensile Strength |

Elongation at break > 350% |

|

Raw Material |

The raw material is 100% virgin HDPE Grade PE100 |

|

Color |

ES-ISO 4427: Black with blue stripes or as per ISO standards

|

|

Length |

As per customer's requirements |

POLYVINYL CHLORIDE (PVC)

TDI’s PVC pipes have properties of corrosion-resistant and scale build-up, lightweight, longer product life (more than 50 years), chemical resistance and UV stability, quicker installation time, clear environmental advantages, and high flow rates. All TDI’s PVC pipes are manufactured according to ISO 1452 and can be confidently used with the following applications:

- Water Supply: TDI uPVC pipes will not affect the taste color or smell of drinking water.

- Agriculture and Irrigation: TDI uPVC pipes are ideal for agricultural irrigation systems.

- Industrial: TDI uPVC pipes are resistant to most chemicals so make an ideal choice in many industrial pipeline applications.

- Drainage and Sewer System

- Rainwater Collection

- Electrical and Telecommunications

|

Standards: |

ISO 1452 |

|

Material |

100% pure uPVC resin and additives |

|

Joints |

solvent cement weld sockets & rubber ring seal joint |

|

Temp. Range |

0˚C - 60˚C |

|

Tensile Strength |

Min. 80 N/mm2 |

|

Color |

Dark grey, Light Grey, Orange… |

|

Length |

Pipes are normally supplied in 6m overall length, and can also be supplied in 5.8m overall length to fit inside containers. |

HDPE BUTT WELD FITTINGS

Tana Drilling and Industries PLC has started to manufacture and supply a complete range of HDPE butt weld fittings for use exclusively with butt welding. These fittings are often a preferred option for butt weld contractors as they are compact, easily stacked for simplified transportation and storage, and excellent for prefabricated pipe works.

Butt fusion involves the simultaneous heating of the ends of two pipe/fitting components which are to be joined until a molten state is attained on each contact surface. The two surfaces are then brought together under controlled pressure for a specific cooling time and a homogeneous fusion joint is formed. The resultant joint is fully resistant to end loads and has comparable performance under pressure to the pipe itself.

Butt welding is a very economical and reliable jointing technique for making permanently welded joints by way of a thermodiffusion process, requiring only butt-welding equipment. TDI supplies both fittings with short spigot ends and fittings with long spigot ends are suitable for butt welding.

Concentric and eccentric equal tees, 90° bends (elbows), cross tees, end caps, and Y-Branches are all part of the comprehensive range of butt weld fittings manufactured and supplied by TDI. We have Production Capacity in all sizes of HDPE butt-welded/Segmented fittings up to Ø400 mm nominal diameter. The offered items are fabricated utilizing quality sanction PE-100 material and propelled manufacturing machinery, instruments, and dynamic innovation and technology.